The Mushroom Color Atlas is a living study of color derived from dyeing with mushrooms. The wide-ranging forages will extend and evolve this atlas over time. Color studies will be conducted and results added to the atlas. Mycopeeps from many locations will continue to join us on this journey and contribute their knowledge. The resulting colors are informed by a myriad of factors that influence, inform and change their chromatic outcome, but the processes and steps involved in each color study will remain consistent:

- Foraging, gathering and preparing the dye mushrooms.

- Sourcing, scouring and mordanting the fibers.

- Creating dye baths and coaxing color from the dye mushrooms.

- Dyeing the fibers in the soluble mushroom dye baths.

- Laking the dye baths to transform them into insoluble mushroom pigments.

- Making watercolor paint from the mushroom pigments.

- Using the watercolor to paint the swatches.

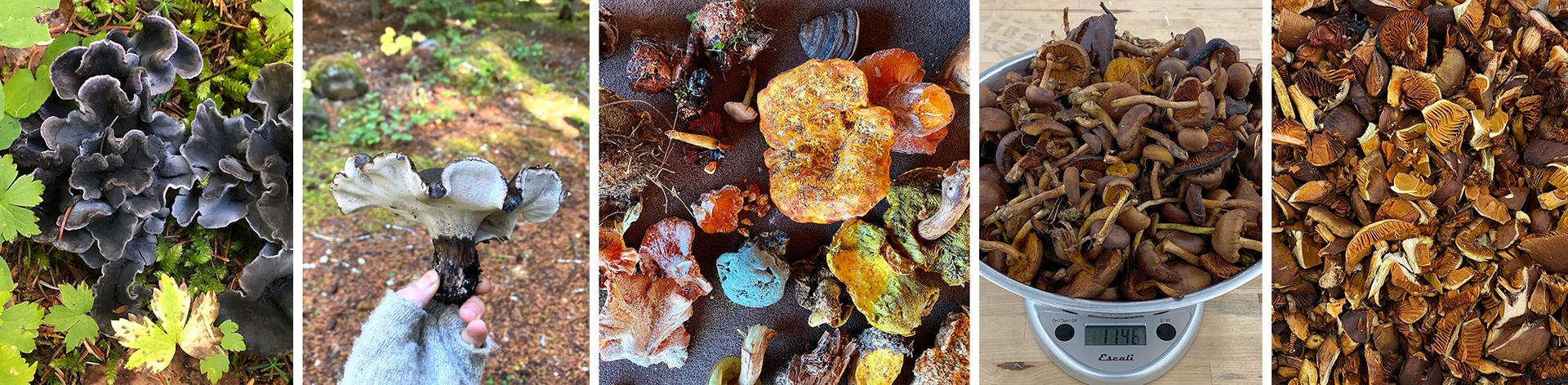

The first step is to obtain mushrooms that yield color. This Atlas has resources to help educate and direct foragers in that pursuit, but this is NOT a field guide, it is purely a study of color extracted from foraged dye mushrooms. Once dye mushrooms are obtained, there are many factors that affect color rendering.

- Foraging: I foraged for all the wild mushrooms used in this Atlas except for a handful that were lovingly gifted to me. Learning how to identify mushrooms and become a conscientious and thoughtful forager is critical. You will need to make sure you are foraging in approved areas and you are not trespassing on private property. You will need to ensure that you have the permits required to remove wild mushrooms from the field. As with any type of wild foraging you will want to be disciplined and economical and leave some mushrooms behind for the future. An experienced and sustainable forager will not disturb delicate environments, they will only forage for samples to aid in the identification of the mushroom. You will be surprised how few mushrooms you need to make dyes and pigments.

- Mushrooms: The age and maturity of the mushrooms will significantly impact the dye. Typically you forage dye mushrooms when they are older. Most of the mushrooms used in this Atlas were dried and stored for years or months prior to processing. Some mushrooms were freshly picked, as indicated.

- Parts Used: Often the entire mushroom was used in the process but sometimes just the caps or just the stems were used.

- Weight: Weighing the mushrooms to inform how much you actually need is important. If you don’t have enough mushrooms and you have a lot of fiber you won’t get much color.

- Weight of Goods : Weight of Fiber: The rule of thumb for natural dyes is the weight of the goods (WOG) should be the same amount as your weight of fiber (WOF). It is converted to a ratio WOG : WOF or 1:1. However there are exceptions to this general rule because some mushrooms are strong dyers that yield a lot of color so you need very little and vice versa. If you have a mushroom that is a strong dyer you will need less of it than the total weight of fiber. The ratio would be represented as 1:2 meaning you need half as much mushroom as the weight of fiber to yield a good dye result.

- Fresh Mushrooms: It is hard to get your ratio down when using fresh mushrooms because the weight is thrown off by the amount of water in the mushroom. One trick is to eyeball your pile of mushrooms and if it is the same size or larger than your pile of fiber, you should have enough mushrooms to get color.

- Surface Exposure: To get as much surface area exposed to the water the mushrooms are ground in a coffee grinder. Fresh mushrooms, that don’t lend themselves to grinding, were chopped into the smallest pieces possible.

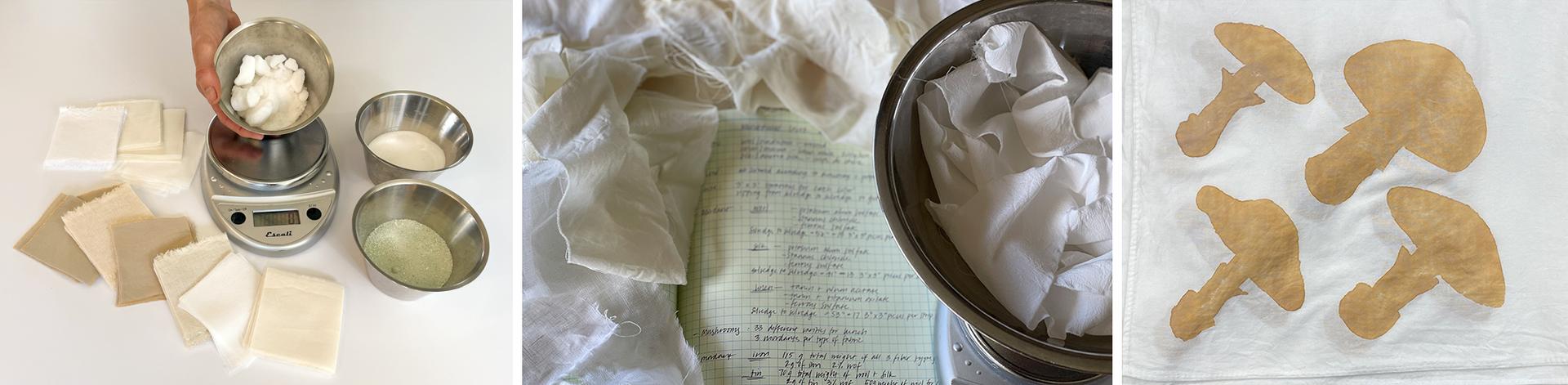

Mushroom dyes prefer natural fibers and in this Atlas only wool, silk, and linen were used. The colors will respond to the fiber differently based on its color, weave, density, weight, etc.

- Wool: Worsted wool was sourced from Pendleton Wool. A single swatch of wool weighed 1 g.

- Silk: Crepe de chine, 100% natural silk, was sourced from Aurora Silks. A single swatch of silk weighed 1 g.

- Linen: Organic linen was sourced from Maiwa. A single swatch of linen weighed 2 g.

- Treatment: The fabric was cut into 3.25” squares to account for shrinkage for a finished 3" x 3" fabric swatch. Three pieces of each fiber type were used for a total weight of 12 g (WOF). Prior to putting the fiber into the dye baths they were wetted out for 30 minutes.

Starting with clean, washed, fibers that are ready to accept the dye is a critical, often forgotten, step in the process. Even fibers that are said to be Prepared for Dyeing (PFD) can have remnants of the manufacturing process on the fibers inhibiting their ability to evenly soak up the dye.

- Temperature: Scouring technically means bringing your fibers to a boil, which is not recommended. Refer to these temperature guidelines for fiber types.

- Wool: Scoured with Orvus paste at 1% WOF at 160° Fahrenheit/71° celsius for 1 hour.

- Silk: Scoured with Orvus paste at 1% WOF at 140° Fahrenheit/60° celsius for 30 minutes.

- Linen: Scoured with Synthrapol soap at 1% WOF + 1% Soda Ash WOF at 180° Fahrenheit/82° celsius for 1 hour.

To get natural colors to affix to natural fibers you need to mordant your fibers. The type of mordant you use will inform your dye results and can often modify a color, resulting in a range of colors across different fiber types and mordants for one mushroom.

- Mordanting: There are many processes for mordanting fibers and each fiber has many alternate methods that can be used. The types of mordants and the respective percentage for each is indicated below. For each fiber type I used the following methods.

- Wool: Water was warmed, mordant was dissolved in the warm water, fibers were dropped in and everything was heated up to 180° Fahrenheit/82° Celsius. The pot was pulled off the burner and let to cool with the fibers, often gently stirred, in the pot for 24 hours after which the fibers were removed, rinsed and hung to dry.

- Silk: Water was warmed, mordant was dissolved in the warm water, fibers were dropped in and everything was heated up to 160° Fahrenheit/71° Celsius. This temperature was maintained for an hour and the fibers were often gently stirred, after which the fibers were removed, rinsed and hung to dry.

- Linen: (Titanium Oxalate & Iron) Water was warmed, mordant was dissolved in the warm water, fibers were dropped in and everything was heated up to 180° Fahrenheit/82° Celsius. The pot was pulled off the burner and let to cool with the fibers, often gently stirred, in the pot for 24 hours after which the fibers were removed, rinsed and hung to dry.

- Linen: (Tannin & Aluminum Acetate) Warm tap water was used, tannin was dissolved in the warm water, fibers were dropped in, often gently stirred, for 2 hours after which the fibers were removed and rung out. These wet fibers that had not been rinsed were immediately put into a pot of warm tap water with dissolved aluminum acetate. The pot was left to cool with the fibers, often gently stirred, in the pot for 24 hours after which the fibers were removed, rinsed and hung to dry.

- Iron: (Ferrous Sulfate) mordant was used at 2% WOF.

- Tin: (Stannous Chloride) mordant was used at 3% WOF.

- Titanium Oxalate: mordant was used at 6% WOF (Linen only).

- Alum: (Aluminum Potassium Sulfate) was used at 15% WOF.

- Alum: (Aluminum Acetate) was used at 6% WOF (Linen only).

- Tannin: (Gall Nut Extract) was used at 10% WOF (Linen in combination with Aluminum Acetate only).

- Cream of Tartar: was used at 6% WOF (Wool only).

For these color studies a very specific dye process was followed to ensure the results would be consistent. To coax color from mushrooms you often have to modify the pH of the dye bath. Therefore, precise measurements were taken and these same dye baths were used to produce the pigment as a secondary step.

- Half gallon jars: A single jar was used for each mushroom dye bath.

- Tamale steamer pot: The steamer had a base that elevated the jars and held up to 5 jars at one time.

- Water: 2 liters of water filled each gallon jar.

- Pre-soaked mushrooms: Some mushrooms, as indicated, were pre-soaked at a minimum of 24 hours prior to cooking, with exceptions noted.

- Temperature: The dye baths were maintained between 140° Fahrenheit/60° Celsius up to 160° Fahrenheit/71° Celsius degrees, with exceptions noted.

- Time: 1 hour cooking time for each dye bath, minimum.

- pH: The dye bath was modified to inform the color results, precisely tracked with a digital pH meter.

- Acidic: (Low pH) Vinegar was added to the dye bath, where noted, at the very beginning within 5 minutes of dropping the mushrooms into the warm water. The vinegar acts as a solvent to help coax color out of the mushroom which results in an acidic dye bath (pH 4-5).

- Alkaline: (High pH) Soda Ash (Sodium Carbonate) was added to the bath within 5-10 minutes of dropping the mushrooms into the warm water. This results in an alkaline dye bath (pH 9-10).

- Straining: The mushrooms were strained from the dye bath before immersing the wetted fibers.

- Fibers: All fibers were added at the same time, with few exceptions. For example, fibers mordanted with iron were added last.

The process of forming a lake from a dye bath is to take a soluble dye, capture the color and turn it into a pigment which is no longer soluble. The resulting pigment can then be used to make paint.

- Ratio: The recipe Catharine Ellis & Joy Boutrup published was used: 10 g of Aluminum Potassium Sulfate for every 1 liter of water and 5 g of Soda Ash/Calcium Carbonate for every 1 liter of water.

- Dye baths: The existing dye baths used to dye the fiber were turned into lakes.

- Straining: The dye baths were strained to remove any debris from the dyeing process.

- Temperature: The dye baths were heated up to 85° Fahrenheit/29° Celsius so minerals could dissolve.

- Jars: Each jar had enough room in it to allow for the precipitate, but to be safe each jar was placed one at a time in a pot to capture any precipitate that bubbled over.

- Alum: (20g) This went in first and was poured directly into the dye bath, stirring and letting it dissolve.

- Soda Ash: (10g) This was dissolved in hot tap water (110° Fahrenheit/43° Celsius) before putting into the dye bath with a quick, minimal stir.

- Precipitate: The chemical reaction created when the two minerals combine (foam and bubble).

- Levigating: When the accumulated color settles to the bottom of the jar.

- Supernatant: This is the liquid that sits above the settled pigment, should be clear. If not clear, the above process was repeated.

- Filter: Pour off the supernatant in the sink, filter the pigment through a coffee filter sitting in a strainer over a container. This process can take a bit of time, ranging from a few hours to a day.

- Rinsing: Fresh clean water was strained through the filter, up to 3 times to wash, clean and dissolve any remaining minerals.

- Storage: Wet pigments were stored in a sealed glass jar with drops of clove oil added. Dried pigments were stored in a glass vial with a cork top.

The pigments were transformed into watercolor paint and the colors were captured on Acquarello, 100% cotton, cold pressed watercolor paper cut to 3” squares. Modifiers were created to reveal a range of paint colors for each mushroom.

- Gum arabic: The binder used to make watercolor paint.

- Water: Added to the pigment as needed.

- Pigments: They were mulled on glass treated with silicon carbide.

- Paper: Pre-wetted with modified water prior to applying the pigment.

- Paint: The pigment was overlaid atop wetted, modified paper except for the base color that used non-treated water.

- Modifier: This was brushed on top of pigment after air drying for one minute. The following modifiers were made to create a range of colors: Alum (Aluminum Potassium Sulfate), Soda Ash (Calcium Carbonate), Citric Acid, Copper Acetate and Iron (Ferrous Sulfate).